次级电池

锂离子二级电池(LIBS)在日本发明,并在世界各地广泛。随着更紧凑和移动电子设备的趋势,应用程序不断增加。这些无数应用程序跨越了紧凑和薄的移动设备,包括智能手机,平板电脑和笔记本电脑;电动电池,用于电动和混合动力车;以及用于住宅太阳能系统和燃料电池的电力存储系统。因此,对次级电池的研究和改进导致了进一步的微型化,更高的能力和改善的安全性。

此外,对液态状态锂离子电池的研究,其中液态电解质和分离器被固体电解质代替,并在将来被广泛追求用于实际使用和普及。由于其提高的能量密度,无液体电解质结构,固态电池有望成为下一代电池,从而减少了点火的可能性和高设计灵活性。目前,正在研究许多情况下,正在研究通过使用涂层生产的大量生产。

- Adhesion in secondary battery manufacturing

- Functionalization and surface processing in secondary battery manufacturing

Adhesion in secondary battery manufacturing

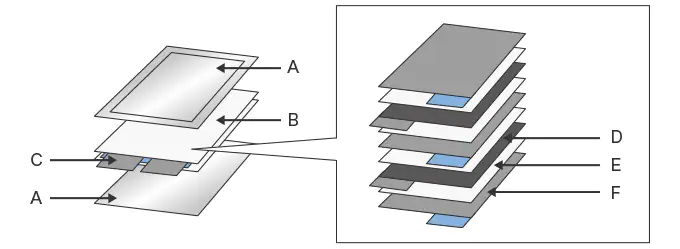

The housings of lithium-ion secondary batteries come in various shapes including cylindrical, square, and pouch (层压)根据最终用途。每种类型的制造过程也有所不同。层压细胞包含一个层状电极(分层元件),该电极用层压膜密封,该膜由铝箔和粘合涂层粘合的树脂膜组成。层压细胞的需求增加了,因为与金属罐类型相比,细胞较薄且更轻,形成柔韧性,并且可以轻松丢弃,而很少有环境负担。

- Adhesion in the manufacturing of laminated cells

- 锂离子二级电池电池由完全密封的分层电极(分层元件)制成,该电极由正面和负电极的交替层组成,介于两者之间。层压细胞尽管结构薄且轻巧。由于大型表面积的高热量耗散,它们还可以在充电/排放期间抑制温度升高。另一个优点是他们的制造成本较低,因为它们可以使用涂料设备大量生产。

- A.层压电影

- B.分层电极(分层元件)

- C.选项卡

- D. Positive electrode

- E. Separator

- F.负电极

The laminated film used for sealing and packing laminated cells (A in the figure above) is generally made of aluminum foil and resin film. The cells are coated with a special adhesive, bonded throughlamination并用于密封分层电极和电解质。用于层压膜的粘合剂需要提供对不同的底物(铝箔和树脂膜)的高粘附力,又可以对内部强酸性电解质进行抗性。

Functionalization and surface processing in secondary battery manufacturing

Coating is a core technology in the manufacturing process of lithium-ion secondary batteries (LiBs). Specific materials coated on the substrate function as the positive electrode (anode), negative electrode (cathode), and separator for isolating them, which combine to form the layered electrode (layered element).

锂离子二级电池制造中的涂料(LIBS)

- A. Negative electrode (Cathode)

- B.阳性电极(阳极)

- C. Separator

- D. Electrolyte

- E.充电

- F.排放

- g .电流收集器

- H. Binder

- I. Active material

Positive electrode (anode) coating

- 阳性电极浆液的示例(基于溶剂)

- An active material, conductive additive, binder, and organic solvent are mixed together to make positive electrode slurry (with organic solvent substituted for water and CMC as the thickener for water-based slurries).

- 活性材料:要使用的活性材料将对容量,电压和特性产生重大影响。选择材料(例如氧化锂,氧化锰锂或铁磷酸锂),混合比和搅拌方法的选择在制造商中有所不同。

- 导电添加剂:该添加剂用于降低内部电阻,从而提高电导率。

- 活页夹:粘合剂用于在当前的收集器箔上粘合混合材料。

- 有机溶剂:这种溶剂促进了材料的混合和搅拌,以调节浆料的粘度,直到适合涂层为止。

- Example of positive electrode slurry coating

- A死皮is used to coat a specific thickness of positive electrode slurry onto the aluminum foil, which works as the current collector. The thickness and weight of the electrode will have a significant effect on the energy density of the battery. Thicker coatings of film are believed to make the capacity larger and the rate characteristics lower. On the other hand, thinner coatings of film make the rate characteristics higher and the capacity smaller.

Negative electrode (cathode) coating

- 负电极浆液的示例(基于溶剂)

- An active material, binder, and organic solvent are mixed together to make negative electrode slurry (with organic solvent substituted for water and CMC as the thickener for water-based slurries).

- Active material: A highly conductive carbon material (such as black lead or lithium titanate) is used. In some case, conductive additive may also be used for the negative electrode to reduce the internal resistance. As with the positive electrode slurry, the active material to be used will have a significant effect on the capacity, voltage, and characteristics. The selection of materials, mixing ratios, and stirring methods vary among manufacturers.

- 活页夹:粘合剂用于在当前的收集器箔上粘合混合材料。

- 有机溶剂:这种溶剂促进了材料的混合和搅拌,以调节浆料的粘度,直到适合涂层为止。

- 负电极浆料涂层的示例

- A死皮用于将负电极浆料的特定厚度涂在铜箔上。通常,负电极形成膜的涂层,而不是正极电极。根据涂层膜厚度的容量和速率特性的变化与正极涂层相同。正极和负电极之间的容量平衡也很重要。在许多情况下,当一侧的涂层变厚时,另一侧的涂层也必须加厚。

分离器制造过程

以下描述了分离器的制造过程,这是用于隔离正极和负电极的重要组件。涂层用于为基础膜增加耐热性。

- Base film manufacturing process: The base film (a microporous membrane) is created from polyolefin material.

- Coating process: A uniform layer of aramid coating fluid (containing aramid polymer) is coated on the base film to form a heat-resistant layer.

- Slit process: The film is cut to the necessary size.

电动汽车(电动汽车)和家用储存电池越来越受欢迎,它使用包含分层电极(分层元件)的层压液。

The manufacturing process for layered electrodes uses positive and negative electrodes that have been cut into sheets for stacking. A sheet of negative electrode is placed as the outermost layer, and then the other components are stacked on it in the order of separator, positive electrode, separator, negative electrode, and so on. These stacked components are packaged with electrolyte to create a cell.

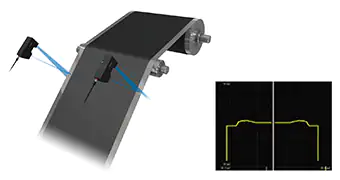

主题:控制电池制造中的涂料质量

The coating thickness of electrode materials has a significant effect on capacity, voltage, and rate characteristics. In order to ensure mass production that satisfies the designed performance and specifications, it is necessary to ensure continuous and uniform coating to maintain the target thickness. Any problem on the coated surface, such as thickness variations or high end portions, will have a significant effect on the quality and performance of the battery product. As such, high-speed and high-accuracy inline measurement and control of coated surfaces are important.

引入共聚焦位移传感器(能够具有高速和高敏锐的内联测量)来确保稳定的厚度测量和控制,而不会受到粗糙表面或激光无法很好地反射的材料的影响。

Coating defects including high edge portions caused by excessive edge thickness can be detected inline by using the High-Speed 2D/3D Laser Scanner, which uses a wide laser beam emitted through a slit to measure shapes.