E-mobility

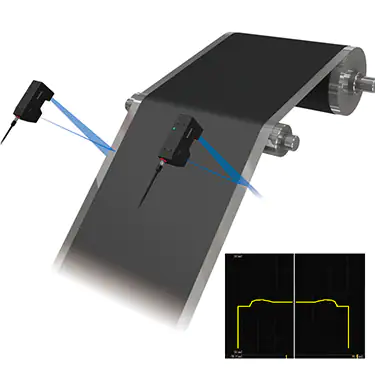

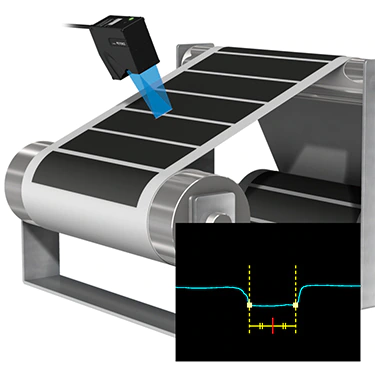

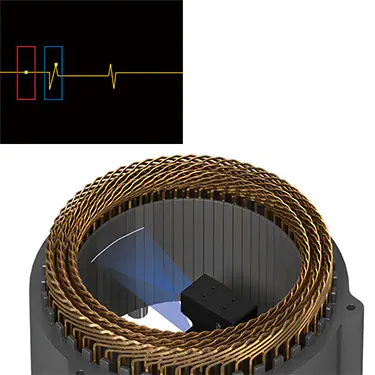

识别边缘珠齿,通过激光分析仪监测边缘形状来减少废物。LJ-X8000可以产生稳定的轮廓(即使在潮湿,黑色表面上)以提供实时涂布过程反馈。

2D/3D Laser Profiler

LJ-X8000系列

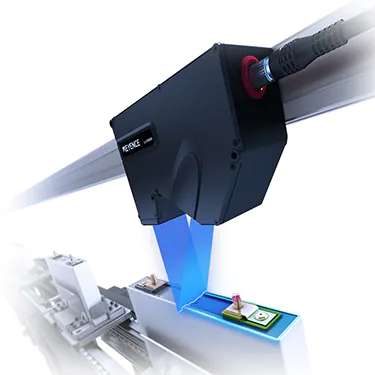

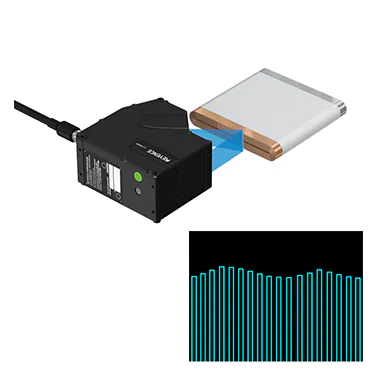

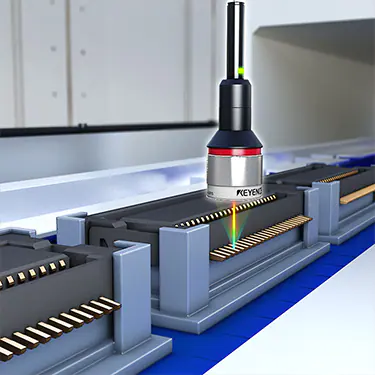

使用相对的非接触式传感器测量电极涂层厚度。CL-3000可以监测湿涂层的厚度,这最小化了应用和检查之间的时间,以减少浪费。同时使用单个控制器在卷筒纸上测量三个位置,以确认厚度和均匀性。

共聚焦位移传感器

CL-3000 series

通过监测日历辊之间的间隙,可以保持对板厚度的紧密控制。LS-9000系列可以测量小于10μm的空隙。

High-speed optical micrometer

LS-9000 series

The TM-X5000 projects the 2D shape of a web's edge to measure thickness with high accuracy. By capturing the surrounding area, the TM can account for web decentering or roll runout to correctly measure the material thickness regardless of surface condition.

Telecentric Measurement System

TM-X5000 series

Detect chipping or dents in laser welded beads using 3D laser profilers. The measurement is unaffected by color or gloss of the weld, making inspection results stable through glare or bead shape variation.

2D/3D Laser Profiler

LJ-X8000系列

使用单个传感器在焊接之前精确地测量每个阀门的位置和浮动,以及检查珠子形状和焊接后焊接。WI-5000不受颜色或材料变化的影响。

3D Interference Measurement Sensor

WI-5000 series

Detect burrs arising on terminals after electrode slitting. With ultra-high-resolution 3200 points/profile measurement, the LJ-X8000 Series produces stable detection even for minute burrs.

2D/3D Laser Profiler

LJ-X8000系列

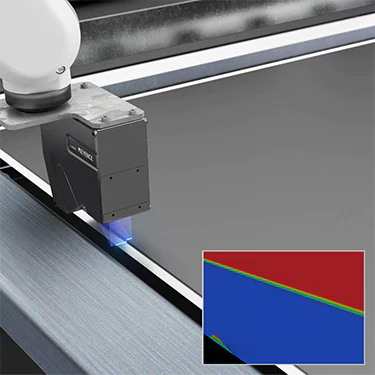

Inspect for lamination misalignment after winding. With a minimum X-resolution of 2.5 μm 0.000098", the LJ-X8000 Series accurately measures the profile of each electrode.

2D/3D Laser Profiler

LJ-X8000系列

Provide feedback about disconnected locations in electrodes before lamination. Accurately acquire the profile of electrode terminals to perform high-accuracy inspection of edge locations.

2D/3D Laser Profiler

LJ-X8000系列

使用非接触式位移传感器的电钢板的内联厚度测量简单。内置的对齐工具和专用夹具使CL-3000成为可靠的解决方案,即使在飘飘期间也能够精确地测量纸张。

共聚焦位移传感器

CL-3000 series

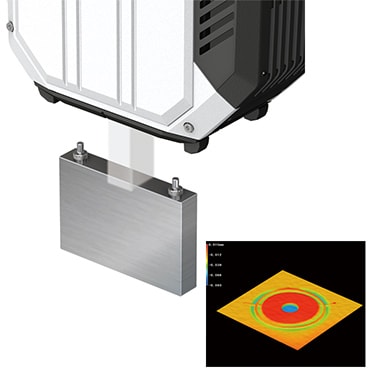

通过测量整体厚度确认堆叠中的层压板数量。如果电机芯具有超过预期的叠片层,则CL-3000可以捕获,以减轻电机性能问题的风险。

共聚焦位移传感器

CL-3000 series

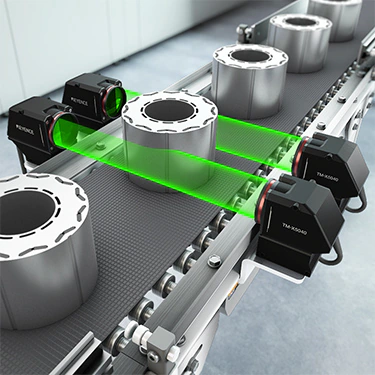

By using two TM-X5000 Series sensors, you can check the outer diameter and cylindricity of lamination stacks with larger diameters.

Telecentric Measurement System

TM-X5000 series

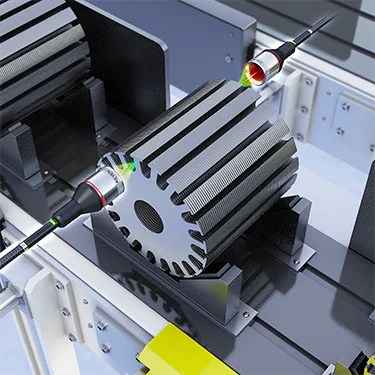

Measure core eccentricity without touching the part. The high-speed sampling of the LS-9000 enables accurate measurement of the core position and diameter during rotation and eliminates operator error.

High-speed optical micrometer

LS-9000 series

组装扁线后,检查绝缘纸是否处于正确位置。即使金属,矩形线和纸等各种材料,LJ-X8000系列也可以高精度地测量。

2D/3D Laser Profiler

LJ-X8000系列

Inspect motor height after powder welding using the LJ-X8000 Series. The 3D laser profiler provides reliable 100% inspection with its high speed and measurement stability.

2D/3D Laser Profiler

LJ-X8000系列

Confirming seal shape helps to prevent oil leakage during the lifespan of the motor. The LJ-X8000 Series can inspect the shape using height data, resulting in more reliable inspection than a general image sensor could provide.

2D/3D Laser Profiler

LJ-X8000系列

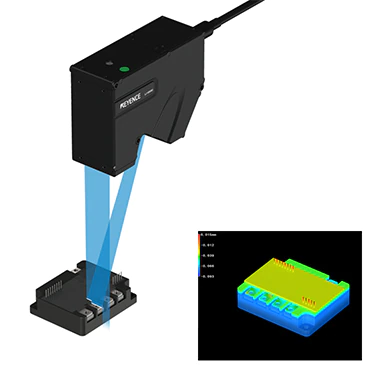

Detect fine chips that can occur when inserting magnets into rotors using 3D inspection. The LJ-X8000 Series provides high resolution 3D images, making it possible to reliably inspect for tiny chips that are difficult to detect from a 2D image.

2D/3D Laser Profiler

LJ-X8000系列

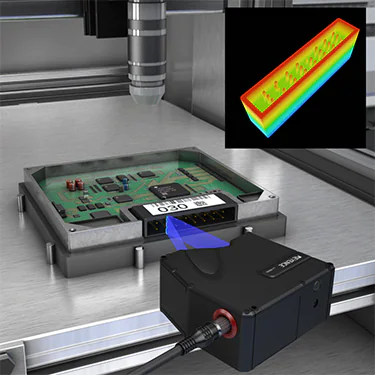

在ECU组件期间检查并行性和浮动,以防止接头接触故障或组件脱离。CL-3000系列可以在无需调整设置的情况下准确测量任何颜色的目标,使得这检查非常稳定。

共聚焦位移传感器

CL-3000 series

正确安装O形圈对于防止可能损坏ECU的漏油是至关重要的。使用LJ-X8000系列,您可以检查精确的装配和记录测量值。

2D/3D Laser Profiler

LJ-X8000系列

Ensure the quality of leads prior to installation in harsh environments by inspecting 100% using laser displacement sensors. The high speed sensors are simple to use and can provide confidence that each part meets the strict requirements of automotive components.

共聚焦位移传感器

CL-3000 series

检查基板翘曲,而不使用2D激光剖面仪停止线路。LJ-X系列可以检查载体和基板之间的间隙,而不必用1D传感器停止和扫描该部件,这减少了检查时间。

2D/3D Laser Profiler

LJ-X8000系列

Stably measure the liquid level of glossy flow solder using the CL-3000. Solder bath can be difficult to measure due to its surface characteristics, but the confocal CL Series can handle the variation in shine and angle, supporting accurate level measurements.

共聚焦位移传感器

CL-3000 series

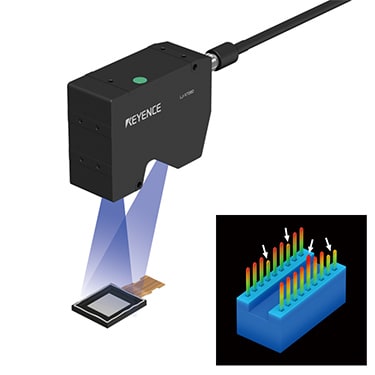

可靠地检查连接器高度并绕线检测弯曲销钉。激光分析仪捕获连接器形状的高分辨率3D图像,提供精确的非接触方法,用于高速分类。

2D/3D Laser Profiler

LJ-X8000系列

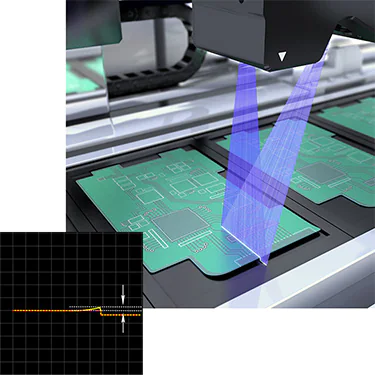

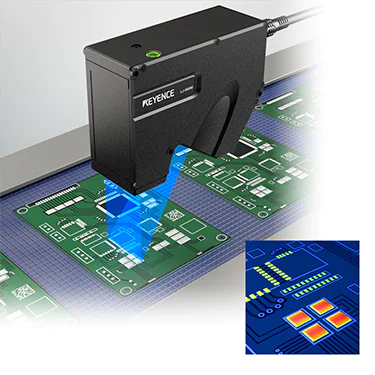

Check for volume and even distribution of solder paste on PCB inline. Multiple areas can be inspected simultaneously from the 3D image.

2D/3D Laser Profiler

LJ-X8000系列

Eliminate operator error in burr measurement by inspecting stamped parts with the WI-5000. The WI can automatically measure the height of burrs relative to a surface, leading to improvements in inspection speed and accuracy over measuring microscopes.

3D Interference Measurement Sensor

WI-5000 series

Measure the position and projection of connector terminals simultaneously. Conventionally, two measurement steps were required using an image processing system and a contact sensor. The LJ-X8000 Series can perform both inspections simultaneously. This achieves cost reduction by reducing the amount of installed equipment.

2D/3D Laser Profiler

LJ-X8000系列

Measure the flatness of the terminals of power modules. The target is detected by its surface and the flatness is measured based on the reference plane calculated with the least squares fitting method. The errors caused by the tilted positions of targets can be canceled, which ensures accurate inspection.

2D/3D Laser Profiler

LJ-X8000系列

Conventionally, a vision sensor was used for OK/NG judgment based on the area. Since the LJ-X8000 Series can measure the volume and position of paste application, it can reduce material costs and support higher component densities.

2D/3D Laser Profiler

LJ-X8000系列